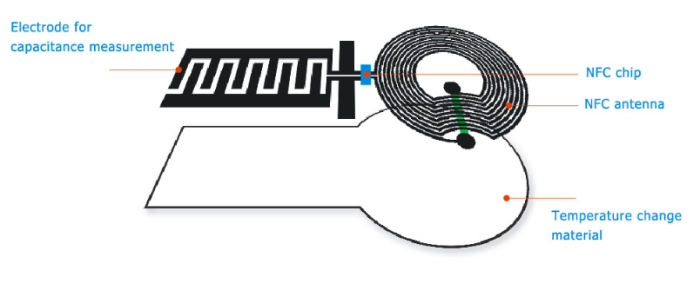

Humidity measurement tags are also known as RFID humidity cards and moisture-proof tags; electronic tags based on passive NFC and used to monitor the relative humidity of items. Paste the label on the surface of the item to be detected or place it in the product or package to monitor the humidity change in real time.

Measuring Equipment and Methods:

Mobile phones or POS machines or readers with NFC functions etc, It can measure the ambient humidity with the test equipment close to the NFC antenna of the tag;

RFID humidity tags are mainly used in the food industry in cold chain logistics and food processing to ensure food safety by real-time monitoring of ambient temperature.

Cold chain transportation temperature monitoring:

RFID temperature tags can record the ambient temperature during transportation in real time. Combined with the GPS positioning system, logistics companies can accurately track the location and transportation status of food. If the temperature is abnormal (such as frozen food thawing or refrigerated food exposed to high temperature environment), the system will immediately trigger an early warning to prevent spoiled food from entering the market.

Environmental control in the processing stage

In food processing workshops, RFID temperature tags are used to monitor the operating environment temperature of equipment (such as refrigeration equipment, processing area temperature control) to ensure that the production process meets safety standards. Some tags can withstand high temperature environments (such as 220℃ for a short time) and are suitable for high temperature processing scenarios.

As the food industry attaches great importance to food safety and the need for monitoring the production environment increases, the application trend of RFID humidity tags in the food industry is also gradually increasing:

-Improve food safety

-Optimize supply chain management

-Improve production efficiency

-Strengthen brand credibility

Post time: Jul-21-2025